|

|

|

Nation: |

USA |

|

Manufacturer: |

General Dynamics Corp, Lockheed Martin |

|

Type: |

multirole class A fighter |

|

Year: |

Winner of competention February 1972

Firts prototype (s/n 72-01567) started 13th December 1973

Second prototype YF-16 (s/n 72-01568) started 9th May 1974

Until January 1975, 11 F-16A, 4 F-16B

Officially chosen 7th June 1975

First definitive model F-16A flown 8th Decemder 1976

First definitive model F-16B flown 8th August 1977 |

|

Engine: |

F-16A/B: one Pratt and Whitney F100-PW-200.

F-16A/B: one Pratt and Whitney F100-PW-220E.

F-16C/D: one Pratt and Whitney F100-PW-200/220/229 or General

Electric F110-GE-100/129 SOUND |

|

Thrust: |

F-16A/B, 23,830 pounds(10,794 kilograms)

F-16A/B MLU, 23770 pounds (10,767 kilograms)

F-16C/D, 27,000 pounds(12,150 kilograms) |

|

Versions: (Detailed) |

|

A,B |

C,D |

|

31 ft (9.45 m) |

32 ft, 8 in (9.8 m) |

|

47 ft 8 in (14.52 m) |

49 ft, 5 in (14.8 m) |

|

16 ft 5 in (5.01 m) |

16 ft (4.8 m) |

|

|

3.2 |

|

|

18 ft 31 in (5.58 m ) |

|

|

7 ft 9 in (2.36 m) |

|

|

13 ft 11 in (4 m) |

|

|

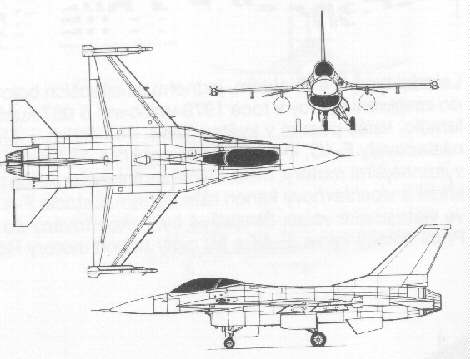

Wingspan: (over

missile launchers) |

|

Lenght: |

|

Height: |

|

Wing aspect ratio |

|

Tailplane span |

|

Whell track |

|

Wheelbase |

|

Weight: |

F-16A/B: 33,000 lb (14,968 kg) /full loaded/

F-16C/D Block 50/52: 42,300 lb (19,187 kg) /full loaded/

F-16C: F100-PW-229/F110-GE-229 ... 8,433 kg (18,591 lb)/8,581

kg (18,917 lb) /empty/

F-16D: F100-PW-229/F110-GE-229 ... 8,645 kg (19,059 lb)/8,809

kg (19,421 lb) /empty/ |

|

Max internal fuel (JP-8) |

F-16C: 3,249 kg (7,162 lb)

F-16D: 2,687 kg (5,924 lb) |

|

Max external fuel (JP-8) |

3,208 kg (7,072 lb) |

|

Maximum takeoff weight: |

37,500 pounds (16,875 kilograms) |

|

Maximum speed: |

1,319 mph (2,123km/h) at 39,370 ft (12,000 m) |

|

Ceiling: |

50,000 ft (15,240 m) |

|

Radius of action: |

676 - 866 n miles (1,252 - 1,604 km) |

|

Ferry range: |

1,961 - 2,276 n miles (3,632 - 4,215 km) |

|

Crew: |

version A, C: 1; B, D: 2 or 1 |

|

Armament: |

General Electric M61A1

20mm six-barrel cannon and two wingtip Sidewinder

or Sparrow air-to-air missiles; nine

additional hardpoints capable of carrying up to 15,200 lbs of

other stores. |

|

Systems: |

AN/APG-66/68 pulsed-Doppler

radar

AN/AAQ-13 LANTIRN NAVIGATION POD

AN/AAQ-14 LANTIRN/SHARPSHOOTER

AN/AAQ-20 PATHFINDER NAVIGATION POD

AN/ASQ-213 HARM TARGETING SYSTEM POD

AN/ALQ-119 ECM POD

AN/ALQ-131 ECM POD

AN/ALQ-178 internal ECM

AN/ALQ-184 ECM POD

AN/ALR-56M threat warning receiver [F-16C/D

Block 50/52]

AN/ALR-69 radar warning system (RWR)

AN/ALR-74 radar warning system (RWR) [replaces AN/ALR-69]

AN/ALE-40 chaff/flare dispenser |

|

|

|

Features

The General Dynamics/Lockheed Martin Fighting

Falcon [ versions ] is considered

by many to be the most agile modern fighter. Less than half the

weight of the F-14,

it carries a larger payload; less than one-fourth the cost of

the F-15, it has superior maneuverability. In addition, advanced

avionics and electronics give it excellent air-to-ground precision.

The F-16 can deliver a crippling ground strike and still maintain

a credible air threat.

In an air combat role, the F-16's maneuverability and combat

radius (distance it can fly to enter air combat, stay, fight

and return) exceed that of all potential threat fighter aircraft.

It can locate targets in all weather conditions and detect low

flying aircraft in radar ground clutter. In an air-to-surface

role, the F-16 can fly more than 500 miles (860 kilometers),

deliver its weapons with superior accuracy, defend itself against

enemy aircraft, and return to its starting point. An all-weather

capability allows it to accurately deliver ordnance during non-visual

bombing conditions.

In designing the F-16, advanced aerospace

science and proven reliable systems from other aircraft such

as the F-15 and F-111 were selected. These were combined to simplify

the airplane and reduce its size, purchase price, maintenance

costs and weight. The light weight of the fuselage is achieved

without reducing its strength. With a full load of internal fuel,

the F-16 can withstand up to 9 G's -- nine times the force of

gravity -- which exceeds the capability of other current fighter

aircraft.

The cockpit and its bubble canopy give the

pilot unobstructed forward and upward vision, and greatly improved

vision over the side and to the rear. The seat-back angle was

expanded from the usual 13 degrees to 30 degrees, increasing

pilot comfort and gravity force tolerance. The pilot has excellent

flight control of the F-16 through its "fly-by-wire"

system. Electrical wires relay commands, replacing the usual

cables and linkage controls. For easy and accurate control of

the aircraft during high G-force combat maneuvers, a side stick

controller is used instead of the conventional center-mounted

stick. Hand pressure on the side stick controller sends electrical

signals to actuators of flight control surfaces such as ailerons

and rudder.

Avionics systems include a highly accurate

inertial navigation system in which a computer provides steering

information to the pilot. The plane has UHF and VHF radios plus

an instrument landing system. It also has a warning system and

modular countermeasure pods to be used against airborne or surface

electronic threats. The fuselage has space for additional avionics

systems.

All F-16s delivered since November 1981 have

built-in structural and wiring provisions and systems architecture

that permit expansion of the multirole flexibility to perform

precision strike, night attack and beyond-visual-range interception

missions. This improvement program led to the F-16C and F-16D

aircraft, which are the single- and two-place counterparts to

the F-16A/B, and incorporate the latest cockpit control and display

technology. All active units and many Air National Guard and

Air Force Reserve units have converted to the F-16C/D.

The Falcon’s versatility is still being explored. The variety

of stores it can carry and wide range of missions it can undertake

with great effectiveness are staggering. The F-16 has proven

itself capable of air superioority, „Wild Weasel,"

strike, and reconnaissance missions without any structural modofications.

The simple addition of the proper external pods or ordnance is

all that is required. There is even an experimental GPU-5 external

gun pod which contains a 30mm cannon firing the same shells as

the A-10’s famous tank-busting Avenger.

Service Life

The Falcon Up Structural Improvement Program

program incorporates several major structural modifications into

one overall program, affecting all USAF F-16s. Falcon Up will

allow Block 25/30/32 aircraft to meet a 6000 hour service life,

and allow Block 40/42 aircraft to meet an 8000 hour service life.

In view of the challenges inherent in operating F-16s to 8,000

flight hours, together with the moderate risk involved in JSF

integration, the Department has established a program to earmark

by FY 2000 some 200 older, Block 15 F-16 fighter aircraft in

inactive storage for potential reactivation. The purpose of this

program is to provide a basis for constituting two combat wings

more quickly than would be possible through new production. This

force could offset aircraft withdrawn for unanticipated structural

repairs or compensate for delays in the JSF program. Reactivating

older F-16s is not a preferred course of action, but represents

a relatively low-cost hedge against such occurrences.

The Air Force will soon be flying only Block

40/42 and Block 50/52 F-16s in its active-duty units. Block 25

and Block 30/32 will be concentrated in Air National Guard and

Air Force Reserve units.

The Fighting Falcon forms the backdone of the USA - Qty.: 2500+

- US tail code marking

|

USA |

Qty. |

Model/Block (detailed) |

Air Combat Command - ACC

[Tactical Air Command - TAC] |

2230 |

YF16A

FSD

A,B/5

A,B/10

A,B/15

C,D/25

C,D/30

C,D/32

C,D/40

C,D/42

C,D/50

C,D/52 |

|

Air Education and Training Command - AETC |

? |

A,B/20

?/52 |

|

Air Force Materiel Command - AFMC |

? |

A,B/?

D/40

?/50 |

Air Force Reserve Command - AFRC

[Air Force Reserve - AFRES] |

? |

C,D/25

C,D/30

C,D/32 |

|

Air National Guard - ANG |

? |

A,B/15ADF

A,B/15

C,D/25

C,D/30

C,D/42

C,D/52 |

|

United States Air Forces in Europe - USAFE |

? |

C,D/25

C,D/40

C,D/50 |

|

Pacific Air Forces - PACAF |

? |

C,D/40

C,D/42

C,D/50

C,D/52 |

|

US Navy - USN |

40 |

A,B/15OCU

N/30

T-N/30 |

|

National Aeronautics and Space Administration

- NASA |

4 |

A,B/XL

A/AFTI

A/15 |

Deployments:

Desert Storm - Iraq

F-16 was used in the Persian Gulf war of 1991 in larger numbers

than any other fighter, with 249 F-16A's and C's seeing action.

The US ANG had two units flying the F-16A, while all the regular

USAF were flying the C models. Many of the F-16s in Gulf were

Block 40 models. However, since LANTIRN targeting pods were still

in short supply, and since the F-15E force had higher priority,

only 72 of the F-16s used during Desert Storm were fitted with

LANTIRN pods (most of them carrying only the navigation pod).

With out the targeting pod, the three squadrons of block-40's

were unable to drop laser guided bombs. The majority of the F-16

force was forced to fly during daylight hours.

Operation Northern Watch & Operation Southern Watch

Following Desert Storm, a no-fly zone was established over

Iraq in April 1991 and designated Operation Southern Watch. The

no-fly zone was the airspace below the 32nd parallel. At the

same time Operation Southern Watch was initiated Operation Provide

Comfort started in the North. This was an effort to protect the

Kurds which were being slaughtered by Saddam's forces and not

allowed into Turkey. When Provide Comfort ended it was renamed

Operation Northern Watch which began on January 1st, 1997. It

was the 36th parallel that was the line of division for Northern

Watch, all Iraqi airspace north of this parallel. The no-fly

zones were regularly patrolled by the USAF and eventually air

forces of various nations.

Operation Allied Force - Balkan

Even more than in operation Desert Storm, operation Allied

Force was dominated by the F-16. This time not only USAF F-16s

participated, but also F-16s from European air forces. A wide

variety of missions were flown with the F-16 including CAP, strike,

reconnaissance, SEAD, etc. The operation started at 19:00 hr

on March 24th, 1999 and lasted until June 10th.

Noble Eagle

Operation Noble Eagle was a direct

result of the attacks on America on September 11th, 2001.

Operation Enduring Freedom

The offensive against whom was behind the attacks on America

on September 11th, 2001, Taliban - Afghanistan.

Operation Iraqi Freedom

F-16 played a major part in this conflict. Many lessons were

learned for the F-16 from the USAF's many recent operations.

The F-16 was a much more formidable weapon then the last war

in Iraq. The operation began with an air campaign, targeted at

destroying the Iraqi defense capabilities, or what was left of

them.

The F-16 also serves in the air forces of :

|

Country |

Qty. |

Model/Block (detailed) |

Bahrain

Royal Bahraini Air Force - RBAF |

22 |

C,D/40 |

Belgium

Belgian Armed Forces/Air Component - BAF |

160 |

A,B/1

A,B/5

A,B/10

A,B/15

A,B/15OCU |

Chile

Fuerza Aerea de Chile

Chilean Air Force - FACh |

28 |

A,B/20MLU

C,D/50 |

Denmark

Flyvevaben

Royal Danish Air Force - RDAF |

77 |

A,B/1

A,B/5

A,B/10

A,B/15 |

Egypt

Al Quwwat al Jawwiya Ilmisriya

Egyptian Air Force - EAF |

220 |

A,B/15

C,D/32

C,D/40 |

Greece

Elliniki Aeroporia

Hellenic Air Force - HAF |

180 |

C,D/30

C,D/50

C,D/52 |

Indonesia

Tentara Nasional Indonesia-Angkatan Udara

Indonesian Air Force - TNI-AU |

12 |

A,B/15OCU |

Israel

Cheil Ha'avir

Israel Defense Force/Air Force - IDF/AF |

362 |

A,B/1

A,B/5

A,B/10

C,D/30

C,D/40

D/52 |

Italy

Aeronautica Militare Italiana

Italian Air Force - AMI |

34 |

A,B/15ADF

A,B/10

B/5 |

Jordan

Al Quwwat al Jawwiya al Malakiya al Urduniya

Royal Jordanian Air Force - RJAF |

36 |

A,B/15ADF

B/20MLU |

Norway

Luftforsvaret

Royal Norwegian Air Force - RNoAF |

74 |

A,B/1

A,B/5

A,B/10

A,B/15

B/15OCU |

Oman

Al Quwwat al Jawwiya al Sultanat Oman

Royal Air Force of Oman - RAFO |

12 |

C,D/50 |

Pakistan

Pakistan Fiza'ya

Pakistan Air Force - PAF |

111 |

A,B/15OCU

A,B/15 |

Poland

Si³y Powietrzne Rzeczpospolitej Polskiej

Polish Air Force - POLAF |

ord.48 |

C,D/52 |

Portugal

Força Aérea Portuguesa

Portuguese Air Force - PoAF |

45 |

A,B/15OCU

A,B/15 |

Republic of China / Taiwan

Chung-kuo Kung Chun

Republic of China Air Force - RoCAF |

150/30? |

A,B/20

C,D/52? |

Singapore

Republic of Singapore Air Force - RSAF |

70 |

A,B/15OCU

C,D/52 |

South Korea

Han-guk Kong Goon

Republic of Korea Air Force - RoKAF |

180 |

C,D/32

C,D/52 |

Thailand

KongTup Arkard Thai

Royal Thai Air Force - RTAF |

54 |

A/10OCU

A,B/15OCU

A,B/15ADF |

The

Netherlands

Koninklijke Luchtmacht

Royal Netherlands Air Force - RNlAF |

213 |

A,B/1

A,B/5

A,B/10

A,B/15

A,B/15OCU |

Turkey

Turk Hava Kuvvetleri

Turkish Air Force - TuAF |

240 |

C,D/30

C,D/40

C,D/50 |

United

Arab Emirates

Al Imarat al Arabiyah al Muttahidah

United Arab Emirates Air Force - UAEAF |

80 |

E,F/60 |

Venezuela

Fuerza Aéra Venezolana

Venezuelan Air Force - FAV |

25 |

A,B/15 |

|

|

Design Features |

Structure |

|

Cantilever mid-wing monoplane of blended wing-body

design and cropped delta planform. The blended wing-body concept

is achieved by flaring the wing/body intersection, thus not only

providing lift from the body at highangles of attack but also

giving less wetted area and increased internal fuel volume. Basic

wing is NACA 64A-204 section with 40o sweepback on leading-edges.

The tail unit is a cantilever structure with sweptback surfaces.

Optional extension of fin root fairing houses ECM equipment in

some aircraft and a brake parachute in other aircraft. Ventral

fins three-quarters along fuselage. |

Wing, mainly of aluminium alloy with 11 spars,

five ribs and single upper and lower skins, is attached to fuselage

by machined aluminium fittings. The fuselage is a semi-monocoque

all-metal structure of frames and longerons built in three main

modules: forward (to just aft of cockpit), centre and aft. Nose

radome built by Brunswick corporation.Highly swept vortex control

strakes along the fuselage forebody increase lift and improve

directional stability at high angles of attack. The tail unit

fin is a multispar, multirib

aluminium structure with graphite epoxy skins, aluminium tip

and glass fibre dorsal fin and root fairing. Tailplanes constructed

of graphite epoxy composite laminate skins mechanically attached

to a corrugated aluminium substructure. Each tailplane half has

an aluminium pivot shaft and a removable full-depth bonded honeycomb

leading-edge. Ventral fins are bonded aluminium skins. |

|

|

|

Engine

|

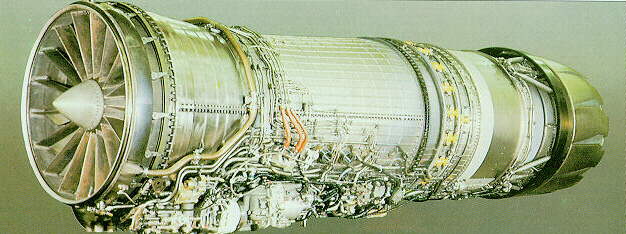

The development of the Pratt & Whitney

F100 turbofan began in August of 1968 when the USAF awarded contracts

to both P & W and General Electric for the development of

engines to be used in the projected F-X fighter, which was later

to emerge as the F-15 Eagle.

In 1970, Pratt and Whitney was declared the winner of the competition

and was awarded the contract for the engine for the F-15. The

engine was to be designated F100. Two versions of the engine

were planned, the F100 for the USAF and the F401 for the Navy.

The latter engine was intended for later models of the F-14

Tomcat, but was cancelled when the size of the planned Tomcat

fleet was cut back in an economy move.

The F100 is an axial-flow turbofan with a bypass ratio of 0.7:1.

There are two shafts, one shaft carrying a three-stage fan driven

by a two-stage turbine, the other shaft carrying the 10-stage

main compressor and its two-stage turbine. For the F100-PW-200

version, normal dry thrust is 12,420 pounds, rising to a maximum

thrust of 14,670 pounds at full military power. Maximum afterburning

thrust is 23,830 pounds.

The

F100 engine was first tried in service with the F-15 Eagle. The

Air Force had hoped that the F100 engine would be a mature and

reliable powerplant by the time that the F-16 was ready to enter

service. However, there were a protracted series of teething

troubles with the F100 powerplants of the F-15, compounded by

labor problems at two of the major subcontractors. Initially,

the Air Force had grossly underestimated the number of engine

powercycles per sortie, since they had not realized how much

the F-15 Eagle's maneuvering capabilities would result in abrupt

changes in throttle setting. This caused unexpectedly high wear

and tear on the engine, resulting in frequent failures of key

engine components such as first-stage turbine blades. Most of

these problems could be corrected by more careful maintenance

and closer attention to quality control during manufacturing

of engine components. Nevertheless, by the end of 1979, the Air

Force was being forced to accept engineless F-15 airframes until

the problems could be cleared up. The

F100 engine was first tried in service with the F-15 Eagle. The

Air Force had hoped that the F100 engine would be a mature and

reliable powerplant by the time that the F-16 was ready to enter

service. However, there were a protracted series of teething

troubles with the F100 powerplants of the F-15, compounded by

labor problems at two of the major subcontractors. Initially,

the Air Force had grossly underestimated the number of engine

powercycles per sortie, since they had not realized how much

the F-15 Eagle's maneuvering capabilities would result in abrupt

changes in throttle setting. This caused unexpectedly high wear

and tear on the engine, resulting in frequent failures of key

engine components such as first-stage turbine blades. Most of

these problems could be corrected by more careful maintenance

and closer attention to quality control during manufacturing

of engine components. Nevertheless, by the end of 1979, the Air

Force was being forced to accept engineless F-15 airframes until

the problems could be cleared up.

However, the most serious problem with the

F100 in the F-15 was with stagnation stalling. Since the compressor

blades of a jet engine are airfoil sections, they can stall if

the angle at which the airflow strikes them exceeds a critical

value, cutting off airflow into the combustion chamber which

results in a sudden loss of thrust. Such an event is called a

stagnation stall. Stagnation stalls most often occurred during

high angle-of-attack maneuvers, and they usually resulted in

abrupt interruptions of the flow of air through the compressor.

This caused the engine core to lose speed, and the turbine to

overheat. If this condition was not quickly corrected, damage

to the turbine could take place or a fire could occur.

Some stagnation stalls were caused by "hard"

afterburner starts, which were mini-explosions that took place

inside the afterburner when it was lit up. These could be caused

either by the afterburner failing to light up when commanded

to do so by the pilot or by the afterburner actually going out.

In either case, large amounts of unburnt fuel got sprayed into

the aft end of the jetpipe, which were explosively ignited by

the hot gases coming from the engine core. The pressure wave

from the explosion then propagated forward through the duct to

the fan, causing the fan to stall and sometimes even causing

the forward compressor stage to stall as well. These types of

stagnation stalls usually occurred at high altitudes and at high

Mach numbers.

Normal recovery technique from stagnation

stalls was for the pilot to shut the engine down and allow it

to spool down. A restart attempt could be made as soon as the

turbine temperature dropped to an acceptable level.

When it first flew, the YF-16 seemed to be

almost free of the stagnation stall problems which had bedeviled

the F-15. However, while flying with an early model of the F100

engine, one of the YF-16s did experience a stagnation stall,

although it occurred outside the normal performance envelope

of the aircraft. Three other incidents later occurred, all of

them at high angles of attack during low speed flights at high

altitude. The first such incident in a production F-16 occurred

with a Belgian aircraft flying near the limits of its performance

envelope. Fortunately, the pilot was able to get his engine restarted

and land safely. The F-16 was fitted with a jet-fuel starter,

and from a height of 35,000 feet the pilot would have enought

time to attempt at least three unassisted starts using ram air.

When the F100 engine control system was originally

designed, Pratt & Whitney engineers had allowed for the possibility

that the ingestion of missile exhaust might stall the engine.

A "rocket-fire" facility was designed into the controls

to prevent this from happening. When missiles were fired, an

electronic signal was sent to the unified fuel control system

which supplied fuel to the engine core and to the afterburner.

This signal commanded the angle of the variable stator blades

in the engine to be altered to avoid a stall, while the fuel

flow to the engine was momentarily reduced and the afterburner

exhaust was increased in area to reduce the magnitude of any

pressure pulse in the afterburner. Tests had shown that this

"rocket-fire" facility was not needed for its primary

purpose of preventing missile exhaust stalls, but it turned out

to be handy in preventing stagnation stalls. Engine shaft speed,

turbine temperature, and the angle of the compressor stator blades

are continuously monitored by a digital electronic engine control

unit which fine-tunes the engine throughout flight to ensure

optimal performance. By monitoring and comparing spool speeds

and fan exhaust temperature, the unit is able to sense that a

stagnation stall is about to occur and send a dummy "rocket-fire"

signal to the fuel control system to initiate the anti-stall

measures described above. At the same time, the fuel control

system reduces the afterburner setting to help reduce the pressure

within the jetpipe.

The afterburner-induced stalls were addressed

by a different mechanism. In an attempt to prevent pulses from

coming forward through the fan duct, a "proximate splitter"

was developed. This is a forward extension of the internal casing

which splits the incoming air from the compressor fan and passes

some of this air into the core and diverts the rest down the

fan duct and into the afterburner. By closing the the gap between

the front end of this casing and the rear of the fan to just

under half an inch, the designers reduced the size of the path

by which high-pressure pulses from the burner had been reaching

the core. Engines fitted with the proximate splitter were tested

in the F-15, but this feature was not introduced on the F-15

production line, since the loss of a single engine was less hazardous

in a twin-engined aircraft like the Eagle. However, this feature

was adopted for the single-engined F-16.

These engine fixes produced a dramatic improvement

in reliability. Engines fitted to the F-16 fleet (and incorporating

the proximate splitter) had only 0.15 stagnation stalls per 1000

hours of flying time, much better than the F-15 fleet.

In recent years, the USAF became interested

in acquiring an alternative engine for the F-16, partly in a

desire to set up a competitive process between rival manufacturers

in an attempt to keep costs down, as well as to develop a second

source of engines in case one of the suppliers ran into problems.

In search of a source for an alternate engine for the F-16 and

for the Navy's F-14 Tomcat, in 1984 the Department of Defense

awarded General Electric a contract to build a small number of

F101 Derivative Fighter Engines (DFE) for flight test. The DFE

was based on the F101 used in the B-1 but incorporated components

derived from the F404 engine used in the F/A-18. The Navy decided

to adopt the DFE as a replacement for the Tomcat's TF30 turbofan,

but the USAF announced that they were going to split future engine

purchases between Pratt & Whitney and General Electric. GE

was given a contract for full-scale development of its new engine,

which was to be designated F110.

The

General Electric F110 is similar in size to the Pratt & Whitney

F100. The F110 has a three-stage fan leading to a nine-stage

compressor, the first three stages of which are variable. The

bypass ratio is 0.87 to 1. The annular combustion chamber is

designed for smokeless operation, and has 20 dual-cone fuel injectors

and swirling-cup vaporizers. The single-stage HP turbine is designed

to cope with inlet temperatures as high as 2500 degrees F (1370

C). Blades are individually replaceable without rotor disassembly.

An uncooled two-stage LP turbine leads to a fully-modulated afterburner.

When afterburning is demanded, fuel is injected into both the

fan and core flows, which mix prior to combustion. The

General Electric F110 is similar in size to the Pratt & Whitney

F100. The F110 has a three-stage fan leading to a nine-stage

compressor, the first three stages of which are variable. The

bypass ratio is 0.87 to 1. The annular combustion chamber is

designed for smokeless operation, and has 20 dual-cone fuel injectors

and swirling-cup vaporizers. The single-stage HP turbine is designed

to cope with inlet temperatures as high as 2500 degrees F (1370

C). Blades are individually replaceable without rotor disassembly.

An uncooled two-stage LP turbine leads to a fully-modulated afterburner.

When afterburning is demanded, fuel is injected into both the

fan and core flows, which mix prior to combustion.

All F110s ordered by the USAF were for the F-16 fleet, with the

F-15 retaining the F100. The choice of engines for the Fighting

Falcon began with the Fiscal Year 1985 Block 30 F-16C/Ds. About

75 percent of the F-16s purchased from that time on by the USAF

were powered by the GE engine, with the remainder being powered

by the P & W engine. However, it is not intended that individual

units operate with F-16s powered by two different engine types,

since that would create a spare parts and logistics nightmare.

The choice of engines for the F-16 is made at the Wing level.

In an attempt to address some of the reliability problems of

its engine, Pratt & Whitney developed the -220 model of its

F100 turbofan. It has the same thrust as the -200, but is much

more reliable, having improvements which radically lowered the

number of. unscheduled engine shutdowns. Many older -200 engines

were rebuilt to the -220E standard, becoming directly interchangeable

with new-build -220 engines.

In an attempt to make the F100 more competitive with the General

Electric F110, Pratt & Whitney introduced the more powerful

F100-PW-229 version in the early 1990s. This engine is rated

at 29,100 pounds of thrust with full afterburner. It has a higher

fan airflow and pressure ratio, a higher-airflow compressor with

an extra stage, a new float-wall combustor, higher turbine temperatures,

and a redesigned afterburner. It has about 22 percent more thrust

than previous F100 models. The first F-16s powered by the -229

engines began to be delivered in 1992. However, the degree of

mechanical changes introduced in the -229 make it impractical

to rebuild -200 or -220E engines to -229 standards.

On the export market, the higher thrust of

the F110 made it the engine of choice through the mid to late

1980s. The more powerful F100-PW-229 finally gave P&W the

chance of re-entering the export market. In 1991, South Korea

chose the F100-PW-229 for its license-built F-16s, maintaining

engine commonality with F-16Cs and Ds that were purchased earlier

from the USA.

The F100-PW-200+ is intended for foreign air

forces which operate significant numbers of F-16s that are powered

by -200 and -220E engines, but which are denied access to the

more powerful -229. It combines the core of the -220 with the

fan, nozzle, and digital control system of the -229. It develops

around 27,000 pounds of thrust with afterburning.

|

|

Flying Controls

/ Cockpit

|

Leading-edge

manoeuvring flaps are programmed automatically as a function

of Mach number and angle of attack. The increased wing camber

maintains lift co-efficients at high angles of attack. These

flaps are one-piece bonded aluminium honeycomb sandwich structures

actuated by a Garrett drive system using rotary actuators. The

trailing-edges carry large flaperons (flap/ailerons), which are

interchangeable left with right and are actuated by National

Water Lift integrated servo-actuators. The maximum rate of flaperon

movement is 80o/s. Interchangeable, all-moving tailplane halves.

Split speed-brake inboard of rear portion of each horizontal

tail surface to each side of nozzle, each deflecting 60o from

the closed position. National Water Lift servo-actuators for

rudder and tailplane. Leading-edge

manoeuvring flaps are programmed automatically as a function

of Mach number and angle of attack. The increased wing camber

maintains lift co-efficients at high angles of attack. These

flaps are one-piece bonded aluminium honeycomb sandwich structures

actuated by a Garrett drive system using rotary actuators. The

trailing-edges carry large flaperons (flap/ailerons), which are

interchangeable left with right and are actuated by National

Water Lift integrated servo-actuators. The maximum rate of flaperon

movement is 80o/s. Interchangeable, all-moving tailplane halves.

Split speed-brake inboard of rear portion of each horizontal

tail surface to each side of nozzle, each deflecting 60o from

the closed position. National Water Lift servo-actuators for

rudder and tailplane.

|

|

1.LANDING

GEAR HANDLE

moving the gear handle up retracts the landing gear once the

aircraft is airborn.

2.AOA(Angle of Attack) Indicator

The AOA indicator is an instrument that shows the angle of attack

of the aircraft. In order to genirate lift, the jet needs to

have a positive angle of attack or fly at a positive angle into

the relative wind (airflow).

3.Airspeed Indicator

The airspeed indicator shows the aircraft's airspeed in hundreds

of knots. when the red needle is on the "4", you going

400 knots.

4.MDF (Multi Functional Displays)

Two displays on either side of the centre console in the cokpit

that can show all radar modes including combat and navigation,

as well as other vital information.

5.THREAT WARNING SYSTEM

This system detects radar contacting your aircraft and detemines

its type, strength and bearing. |

6. HUD (heads-up-display)

A glass panel in front of the cockpit that shows important navigation

and weapons information.

7.ICP (Integrated Control Panel)

Panel used for weapons release, landing, navigation and Communications.

8. Oil Pressure Indicator

The Oil pressure indocator dipsays engine oil pressure, ranging

from 0 to 100 psi (pounds per squar inch).

9.RPM (Revolutions Per Minute) Indicator

The RPM indicator displays the engine revolutions per minute.

RPM is expressed as a percentage from 0% to 100%

10. Nozzle Position Indocator

This instrument dispalys the position of the engine nozzle.

the indicator wil be mostly open at at idle, closed at Mil power

(100% thrust), and fully open at full afther burner.

11. VVI (Vertical Velocity Indicator)

The vertical Velocity Indicator is an instrument that shows your

rate of climb or descent in feet per minute.

12. ADI(Attitude Direction Indicator)

The instrument that displays the aircraft pitch and control.

13. CONTROLSTICK:

The F-16C/F users "fly-by-wire" Technolgy on an F16

the stick does not control cables that are linked to the surface,

but tather inputs to a computer which in turn controls servos

or hydaulics for the flaps and rudder, ect...

14. HIS (Horizontal Situation Indocator)

The HSI is a round moving dial that shows the aircraft's compass

heading. When the aircraft turns, the dial moves to indicate

the change in aircraft heading.

15. ALTIMETER

The altimete shows the height of the aircraft sbove MSL(Mean

Sea Level)

16. Eject Handle

17. Trottle |

|

|

Cockpit of F16A |

Stick |

|

Cockpit of F16C |

|

Cocpkit of F16A |

Throttle quadrant |

|

HUD F16 C/D and F16 A |

|

Antenna locations |

Exterior lighting |

Pedals |

|

F-16A cockpit schema |

|

|

EXPLOSIVE

FRACTURING OF AN F-16 CANOPY FOR THROUGH-CANOPY CREW EGRESS

Laurence J. Bement NASA Langley

Research Center Presented at the The 38th Annual SAFE Symposium

October 9-11, 2000 Reno, Nevada

ABSTRACT

Through-canopy

crew egress, such as in the Harrier (AV-8B) aircraft, expands

escape envelopes by reducing seat ejection delays in waiting

for canopy jettison. Adverse aircraft attitude and reduced forward

flight speed can further increase the times for canopy jettison.

However, the advent of heavy, high-strength polycarbonate canopies

for bird-strike resistance has not only increased jettison times,

but has made seat penetration impossible. The goal of the effort

described in this paper was to demonstrate a method of explosively

fracturing the F-16 polycarbonate canopy to allow through-canopy

crew ejection. The objectives of this effort were to: Through-canopy

crew egress, such as in the Harrier (AV-8B) aircraft, expands

escape envelopes by reducing seat ejection delays in waiting

for canopy jettison. Adverse aircraft attitude and reduced forward

flight speed can further increase the times for canopy jettison.

However, the advent of heavy, high-strength polycarbonate canopies

for bird-strike resistance has not only increased jettison times,

but has made seat penetration impossible. The goal of the effort

described in this paper was to demonstrate a method of explosively

fracturing the F-16 polycarbonate canopy to allow through-canopy

crew ejection. The objectives of this effort were to:

- Mount the explosive materials on the exterior

of the canopy within the mold line,

- Minimize visual obstructions,

- Minimize internal debris on explosive activation,

- Operate within less than 10 ms,

- Maintain the shape of the canopy after functioning

to prevent major pieces from entering the cockpit, and

- Minimize the resistance of the canopy to

seat penetration.

All goals and objectives were met in a full-scale

test demonstration. In addition to expanding crew escape envelopes,

this canopy fracture approach offers the potential for reducing

system complexity, weight and cost, while increasing overall

reliability, compared to current canopy jettison approaches.

To comply with International Traffic in Arms

Regulations (ITAR) and permit public disclosure, this document

addresses only the principles of explosive fracturing of the

F-16 canopy materials and the end result. ITAR regulations restrict

information on improving the performance of weapon systems. Therefore,

details on the explosive loads and final assembly of this canopy

fracture approach, necessary to assure functional performance,

are not included.

INTRODUCTION

Many current fighter aircraft use canopy jettison

approaches to clear an uninhibited path for crew egress. This

approach uses pyrotechnic (explosive or propellant-actuated)

devices to first activate latch release mechanisms to free the

canopy assembly from the airframe, and then jettison the assembly

with piston/cylinder thrusters or small rocket motors mounted

at the forward edge of the assembly. The canopy pivots around

aft hinge points. Seat ejection catapults are not initiated until

the canopy has pivoted far enough to insure that the seat and

canopy will not collide. How quickly the canopy assembly is jettisoned

depends on aircraft attitude and forward velocity. A pitch-down

attitude with a flight vector to produce a load on the canopy

would resist jettison. Also, if the aircraft has a low forward

velocity, there would be a minimal aerodynamic assist on the

canopy. Some aircraft, such as the F-15, employ a backup approach

to canopy jettison by using frangible acrylic canopies and designing

the seat to "punch through" to insure egress. The Harrier

(AV-8B) aircraft, a vertical takeoff and landing aircraft, utilizes

an interior-mounted explosive cord to fracture acrylic canopies

to assure an immediately available, unrestricted through-canopy

egress path to reduce crew ejection time. However, on activation,

this explosive cord creates explosive pressure waves and peppers

the crew with highvelocity fragments from the explosive's metal

sheath and from the 3/8th-inch width explosive holder. The crewmembers

also face potential harm from the fractured pieces of canopy

material. Canopy jettison approaches introduce a higher degree

of complexity over through-canopy egress. The advent of using

polycarbonate canopies to resist bird strikes eliminated the

possibility of either "punching through" the canopy

or applying the Harrier approach. However, current projections

of thickness and weight of these canopies indicate that thrusters

and rocket motor jettison approaches are reaching capability

limits. Furthermore, canopy release and jettison approaches require

3 to 4 mechanisms, such as latch actuators, thrusters and rocket

motors. For redundancy, each of these mechanisms requires two

inputs.

A reliable method of severing polycarbonate

to allow through-canopy crew egress would reduce egress time

to expand escape envelopes, simplify aircraft systems and potentially

reduce system weight.

The goal of the effort described in this paper

was to demonstrate a method of explosively fracturing the half-inch

thick polycarbonate portion of the F-16 canopy to allow through-canopy

crew egress.

The objectives for canopy fracturing were

to:

- Mount the explosive materials on the exterior

of the canopy within the mold line

- Minimize visual obstructions

- Minimize internal debris on explosive activation

- Operate within 10 ms (the seat requires at

least 30 milliseconds from catapult initiation to reach the canopy)

- Maintain the shape of the canopy after functioning

to prevent major pieces from entering the cockpit

- Minimize the resistance of the fractured

canopy to seat penetration

The approach for this development, initiated

in references 1, 2 and 3, was to utilize augmented shock wave

severance principles. Parallel explosive cords, as shown in figure

1 in which the cords are proceeding into the plane of the paper,

are initiated simultaneously. The severalmillion psi pressure

generated by the explosive cords transfers into the polycarbonate

and the resulting incident and reflected explosive pressure waves

augment to induce the material to fail in tension. The preliminary

effort began with evaluations on commercial grade polycarbonate.

Then the F-16 canopy was selected for evaluation, since it is

the first production polycarbonate canopy, and service-scrapped

canopies were available. Small (6 X 6-inch plate) specimens were

cut from flat stock and canopies for testing. The evaluation

progressed to small-scale (18 to 30-inch dimension), "mini-panels"

to determine the performance of complete fracture patterns. Finally,

three full-scale canopy tests were conducted.

TEST MATERIALS

This section describes the polycarbonate material

and F-16 canopy tested, as well as the explosive and the explosive

holder used in the tests.

Polycarbonate - Polycarbonate is a long-chain,

organic compound. It has no clear melting point, similar to glass.

It simply gets softer under elevated temperatures until it can

be shaped, and finally, the viscosity becomes low enough to allow

flowing. However, it has a temperature/cycle memory. Each time

it is cycled to a formable point, and with time at temperature,

portions of the organic chains are broken and it becomes more

brittle. Commercial grade (tinted blue) has no limit on the number

of thermal cycle exposures allowed during production or in later

assemblies. Thicker plates are built up by fusing smaller thicknesses

at elevated temperatures. The polycarbonate used in reference

1 was made up in this manner. In contrast, military grade (yellow)

polycarbonate is available only "as cast" with no thermal

cycles. It has the highest resistance to impact fracture.

F-16 canopy - The F-16 canopy, as shown in

figure 1, reference 2, is drape-molded to produce a single piece,

compound curvature shape. It is a three-layer laminate. The inboard,

half-inch thick layer is polycarbonate, created from military

grade flat stock. The 0.050-inch thick inner layer is polyurethane,

which is used to bond the polycarbonate to an outer 1/8-inch

thick layer of acrylic. The canopy is bolted to a metal frame

for the aircraft assembly. The U.S. Air Force supplied 10 scrap

canopies that were rejected following flight service. These canopies

were manufactured by TEXSTAR PLASTICS of Grand Prairie, TX, and

by Sierracin Corporation of Sylmar, CA. Surprisingly different

properties were observed between the two manufacturing sources;

the TEXSTAR canopy could be easily cut with a saber saw, while

the Sierracin unit could not. The Sierracin material softened

around the saw and "gummed" it up, which indicated

that softening occurred at a significantly lower temperature.

The final full-scale canopy fracture demonstrations were conducted

with TEXSTAR units.

Explosive material and holder - The preliminary

tests, described in references 1 and 2, employed a lead-sheathed,

pentaerythritoltetranitrate (PETN) mild detonating cord. For

the remaining tests, a plastic explosive (DuPont trade name "detasheet,"

containing PETN with nitrocellulose and a binder) was obtained

from the inventory of the U.S. Navy. It was selected for use,

because of its flexibility, both in sizing the quantity used

and in conforming to compound curvature of canopies. It works

like "Silly Putty," easily molded, and has sticky,

cohesive/adhesive properties. The material was installed in grooves

cut in acrylic strips, which were in turn bonded to the test

specimens. The explosive cords and holders were bonded into place,

using transparent Dow Corning room temperature vulcanizing silicone

compound (RTV) 3145. The explosive quantity was established by

the size of the groove. The acrylic holder replaced a similar

area removed from the canopy's outer acrylic layer within the

moldline. Note: these explosive materials were used for the experimental

development, but are not recommended for this application, due

to a relatively low melting point and thermal stability. Other,

more stable materials are available.

Explosive pattern - As shown in figure 2,

the layout (grooves) for the explosive severance pattern for

the first full-scale test was on the top centerline, forward

and aft of crewmember, and around the lower extremity. The goal

was to create a "French-door" opening. The initiation

sites (2 for redundancy) were located at aft hinge points, which

also is the closest access between the canopy and aircraft with

the canopy open. On initiation, the explosive propagates upward

and forward from these sites at a velocity of 22,000 feet/second.

Common initiation points at intersections must be used to assure

that the explosive propagation fronts remain in parallel to maintain

shock wave augmentation for long-length applications.

FULL-SCALE TEST DEVELOPMENT PROCEDURE

The development proceeded from small plates

to panels to the full-scale canopy. Small plates - References

1 and 2 describe tests on small (6 X 6-inch) plates cut from

commercial and military grade polycarbonate stock, as well as

from F-16 canopies. The plates were tested with two edges clamped

to simulate conditions within the canopy.

Panels - The same references also describe

"mini-panel" tests with which experiments were conducted

to determine the performance of the "French-door" severance

pattern and of crack propagation. Explosive patterns were placed

close to the edges of the panel. Additional minipanel tests were

conducted in which the panel was framed by 1/8th-inch skin thickness

aluminum to simulate the stiffness afforded by the aircraft installation.

Also, tests were conducted where the explosive patterns were

placed well away from the edge of the panel.

Full-scale tests - All three tests were documented

with high-speed video cameras. The first test, as described in

reference 2, used 2 lead-sheathed explosive cords that were placed

in grooves cut into the exterior layer of acrylic in the pattern

shown in figure 1. The cords were bonded into place with RTV-3145.

The canopy was placed, unsupported, on a flat surface as shown

in the figure. The ambient temperature was approximately 75o

F.

The second test was conducted with two grooves

cut into separate acrylic strips, filled with plastic explosive,

and installed into slots from which the acrylic was removed from

the canopy. The strips were bonded to the canopy using RTV-3145.

Prior to installation of these strips, the 0.050-inch thick polyurethane

middle layer was cut with a razor blade to negate its post-fire

residual strength. Modified explosive patterns were used at the

intersection sites of the severance paths. The objective was

to independently sever these sites to allow end-to-end crack

propagation. Again the canopy was unsupported on a flat surface.

The ambient temperature was approximately 90o F.

The third full-scale test, figure 3, was conducted

with a three-cord configuration of plastic explosive in acrylic

strips and modified intersection charges. (Note: These intersection

charges have been masked to meet ITAR regulations.) Prior to

installation of these strips, using RTV-3145 as a bonding agent,

the 0.050-inch thick polyurethane middle layer was cut with a

razor blade to negate its post-fire residual strength. To simulate

the aircraft installation, the canopy was fastened to a rigid

frame. The canopy was attached to wooden beams that were contoured

to fit the interior of the canopy-mounting interface. The beams

were then fastened to a sheet of 3/4-inch plywood. The test was

conducted at approximately 85 degrees.

TEST RESULTS

Small plates - The small-plate tests (references

1 and 2 and figure 1) revealed that the commercial grade polycarbonate

in thicknesses to 1 inch were easily fractured with the two-cord

explosive arrangement. However, the same test configurations

had little effect on military grade material. A 0.063-inch thickness

layer of polyurethane, between the explosive and polycarbonate,

was required to efficiently couple explosive shock waves to sever

a 0.9-inch thickness, military grade plate. In all small-plate

tests (F-16 and military grade plate stock), this polyurethane

inner-layer remained completely intact after the explosive firing.

Panels

- The mini-panel tests were much simpler and less expensive than

full-scale tests. The tests conducted with both lead-sheathed

explosive cords, references 1 and 2, and subsequently with plastic

explosive in acrylic holders, exhibited completely successful

explosive propagation. The panel tests were somewhat misleading.

The small, relatively flat panels were able to flex inboard on

the desired cutting planes to provide an additional tensile force

on the interior surface. Also, since the explosive patterns were

close to the edges of the panels, internally initiated cracks

easily propagated across the panel. However, subsequent tests

with an aluminum frame and highly curved sections, which stiffened

the panel, and with the explosive patterns placed at least 6

inches from the edge of the panel, complete severance could not

be achieved. Tests with additional charges at the pattern intersections

"punched out" those sites. Tests on highly contoured,

stiff canopy sections, with a 3-cord explosive pattern and with

the ends of the pattern free, achieved complete severance. Finally,

it was observed that the 0.050-inch thick polyurethane middle

layer, which remained completely intact after the explosive firing

had considerable residual strength. Panels

- The mini-panel tests were much simpler and less expensive than

full-scale tests. The tests conducted with both lead-sheathed

explosive cords, references 1 and 2, and subsequently with plastic

explosive in acrylic holders, exhibited completely successful

explosive propagation. The panel tests were somewhat misleading.

The small, relatively flat panels were able to flex inboard on

the desired cutting planes to provide an additional tensile force

on the interior surface. Also, since the explosive patterns were

close to the edges of the panels, internally initiated cracks

easily propagated across the panel. However, subsequent tests

with an aluminum frame and highly curved sections, which stiffened

the panel, and with the explosive patterns placed at least 6

inches from the edge of the panel, complete severance could not

be achieved. Tests with additional charges at the pattern intersections

"punched out" those sites. Tests on highly contoured,

stiff canopy sections, with a 3-cord explosive pattern and with

the ends of the pattern free, achieved complete severance. Finally,

it was observed that the 0.050-inch thick polyurethane middle

layer, which remained completely intact after the explosive firing

had considerable residual strength.

Full-scale

tests - The assembly of the explosive into the canopy in all

three tests was completely successful. No explosive propagation

failures occurred. These tests also demonstrated that the acrylic

strips could replace the outer layer of protective acrylic in

the canopy installation. In the first test (reference 2), approximately

9% of the parent strength remained in lengths between pattern

intersections. However, no fractures occurred at the intersections.

Since the parallel-cord configuration could not be maintained

at these sites, the shock waves could not augment and severance

could not occur. The canopy was effectively held together by

these sites. Considerable deflection was observed as the explosive

impulse pressed the canopy downward, and the unsupported sides

on the flat surface slid outward. Full-scale

tests - The assembly of the explosive into the canopy in all

three tests was completely successful. No explosive propagation

failures occurred. These tests also demonstrated that the acrylic

strips could replace the outer layer of protective acrylic in

the canopy installation. In the first test (reference 2), approximately

9% of the parent strength remained in lengths between pattern

intersections. However, no fractures occurred at the intersections.

Since the parallel-cord configuration could not be maintained

at these sites, the shock waves could not augment and severance

could not occur. The canopy was effectively held together by

these sites. Considerable deflection was observed as the explosive

impulse pressed the canopy downward, and the unsupported sides

on the flat surface slid outward.

In the second test, the additional charges

in the intersections "punched out" those sites and

assisted fracture. Total severance was observed across the aft

transfer path, but, again, the residual strength of the running

lengths, particularly the top/centerline path, remained too high.

Similar deflections to those in the first test were observed.

The results of the third full-scale test (figures

4 and 5) left the canopy essentially intact, as had been observed

in the first two tests. Little deflection was observed in the

high-speed video. The intersections had been punched out, and

the aft transverse path was totally severed, as observed in the

previous test. A major, totally severed crack occurred diagonally

across the right-hand panel, figure 5. This piece was easily

pulled out by hand, figure 6, as were the remaining portions,

as shown in figure 7. Complete severance occurred on every fracture

line.

CONCLUSIONS

This paper describes a successful development

of a unique 3-parallel-cord, augmented shock wave approach to

explosively fracture a tough, polycarbonate F-16 aircraft canopy

to allow through-canopy crew egress. A variety of lessons were

learned in material evaluations, smallscale and mini-panel tests,

and full-scale system tests.

Polycarbonate has a thermal memory that must

be recognized and controlled. To maintain high strength and fracture

resistance of military grade material, thermal elevations to

significant softening point levels must be minimized. That is,

to assure repeatable explosive fracture properties, processes

to create canopies into final shape must be consistent.

Small-scale and mini-panel tests revealed

that it's a long way from testing small pieces to a fullscale

test. Tests on full-scale canopies, which are much stiffer and

which require greater distances of the explosive patterns to

the edge of the canopy, exhibited much higher resistance to fracture.

Special patterns (not presented here, due to ITAR regulations)

had to be developed to both maintain explosive propagation and

punch out the intersections of fracture paths.

All objectives of the effort were met. The

explosive materials can be installed on the exterior of the canopy

within the mold line. The 3-cord explosive pattern is less visually

obstructive than the pattern employed by the Harrier. Installing

the explosive on the exterior eliminates inboard explosive debris

or explosive pressure. The fractured canopy material beneath

explosive intersections can be managed by positioning the intersections

outside the crew envelope, or by structural containment. Explosive

fracture is complete in less than 10 milliseconds; the explosive

materials have detonated completely in less than 1 millisecond.

The canopy maintains its shape after functioning, thus preventing

major pieces from entering the cockpit. The residual strength

of the fractured canopy is small; the seat can easily thrust

aside the severed pieces of the canopy during egress.

The incorporation of this technology into

future crew-escape applications offers a variety of improvements

over canopy jettison systems. Heavier, stronger canopies can

be used. Reducing delay times for canopy jettison can expand

crew escape envelopes. System reliability can be increased; this

is a passive system that has no mechanical interfaces that can

improperly function, and fewer initiation inputs (2 for redundancy)

are required. Canopy jettison systems require one or two latches,

each with a release device, and two thrusters or rockets, totaling

6 to 8 inputs. Canopy fracture should weigh and cost less. It

should have lower maintenance costs. It will be a single, one-time

installation of explosive material, which will last the lifetime

of the canopy. |

|

Pilot`s outfit

|

CWU-27/P Nomex Flying suit

This is exactly the same flight suit worn by United

States Air Force and Navy aircrews all over the world. These

flight suits are absolutely genuine, first quality from the military

production line. They are manufactured to military specification

MIL-C83141A. This is exactly the same flight suit worn by United

States Air Force and Navy aircrews all over the world. These

flight suits are absolutely genuine, first quality from the military

production line. They are manufactured to military specification

MIL-C83141A.

Some companies sell cheaper piece-dyed flight

suits, but we require military-specification, producer-dyed fabric

and zippers made from NOMEX® fiber and thread made from KEVLAR®

fiber.

Even though these flight suits have already

been inspected to tough government standards, we inspect them

again ourselves. And we reject nearly one of every ten because

they just weren’t good enough. You won’t find seconds

or military rejects here. Air Force Sage Green and new Khaki.

Features:

Pleated action back

Round collar

Zipper sleeve pocket with cover

Zipper chest pockets

Zipper thigh pockets

Knife pocket

Zipper leg pockets

Nametag Velcro®

One-inch Velcro® waist tabs

Velcro sleeve tabs

Two-way front zipper

Zipper leg closures |

GS/FRP-2 Nomex Flying gloves

The

fire-resistant flyer's glove (MIL-G-81188) is designated for

use in warm-to-moderate temperature zones and provides protection

in the event of aircraft fire. They are used by all aircrew members

(fig. 4-2). The

fire-resistant flyer's glove (MIL-G-81188) is designated for

use in warm-to-moderate temperature zones and provides protection

in the event of aircraft fire. They are used by all aircrew members

(fig. 4-2).

Configuration:

The gloves are snug fitting and designed to provide maximum dexterity

and sense of touch. If properly fitted they should not interfere

with the operation of the aircraft and use of survival equipment.

The gloves are available in sizes 5 to 11. Since the fabric is

stretchable, the sizes will accommodate any size hand. The gloves

are constructed of soft cabretta gray leather (palm and front

portion of fingers), and a stretchable, sage green, lightweight

knit Aramid fabric (entire back of hand). The cloth portion of

the gloves will not melt or drip, and it does not support combustion.

The fabric does begin to char at 700° to 800°F.

Fitting:

The fire-resistant flyer's glove normally corresponds to the

aircrew member's glove size. Determine the proper size glove

on a trial fit basis. The glove must fit snugly.

Maintenance:

It is the aircrew member's responsibility to clean the gloves.

Repairs or other maintenance actions are performed at the organizational

level or above, and are limited to restitching seams. The gloves

are laundered as follows:

1. Put on the gloves and wash with a mild

soap in water not over 120°F as if washing hands. When the

gloves are clean, rinse and remove them from your hands. Squeeze,

but do not wring the gloves to remove excess water. Never use

a bleaching compound.

2. After removing excess water, place the gloves flat on a towel

and roll the towel to cover the gloves. Ensure that the gloves

do not contact each other and are not exposed to hot air or sunlight.

3. Letting the gloves come in contact with each other may harm

the soft leather palms. The exposure to hot air or sunlight could

cause the gloves to shrink. |

|

CSU-13B/P Anti-G Garment

GENERAL GENERAL

the CSU-13B/P anti-g garment (MIL-A-83406B) provides protection

against high g-forces experienced in high performance aircraft.

CONFIGURATION

The anti-g garments consist of a fire-resistant aramid cloth

outershell which houses a bladder. They are cut away at the buttocks,

groin, and knees. The outershell has waist and leg entrance slide

fasteners, adjustment lacing areas with lacing covers, and leg

pockets with slide fastener closures. The CSU-13B/P also has

a knife pocket on the front left thigh, and thigh take-ups with

slide fasteners. The bladder system is constructed of polyurethane

coated nylon cloth and covers the abdomen, thighs, and calves.

The bladder system is fitted with a hose for connecting directly

to the aircraft anti-g system. |

Gentex CRU-60/P Connector

The

Gentex CRU-60/P Connector meets the requirements of U.S. Air

Force MIL-C-38271B. The CRU-60/P is the standard restraint harness

connector, and connects the aircraft oxygen supply hose from

panel mounted oxygen regulators to demand breathing masks. The

Gentex CRU-60/P Connector meets the requirements of U.S. Air

Force MIL-C-38271B. The CRU-60/P is the standard restraint harness

connector, and connects the aircraft oxygen supply hose from

panel mounted oxygen regulators to demand breathing masks.

The CRU-60/P is normally secured to a dovetail

mounting plate (USAF Drawing No. 57B3657) which is attached to

an airman's parachute harness. The dovetail design of the mounting

plate assures positive locking and prevents flailing during an

ejection.

The CRU-60/P is designed to connect to a standard

three pin bayonet oxygen mask hose connector (Type MS27796).

The aircraft sypply end of the CRU-60/P mates with an MS22058

type connector and incorporates an omni-directional disconnect

to assure proper alignment of disconnect forces during an ejection.

This quick disconnect fitting also provides a disconnect warning

feature. When disconnected from an aircraft oxygen supply hose

the warning valve immediately closes, causing a noticeable resistance

to inhalation, thereby alerting the pilot that disconnection

has occurred.

The CRU-60/P has a bail-out oxygen attachment

nipple which mates with a bail-out bottle supply tube fitting

(Type MS21964-20) |

|

HGU-55/P Helmet

The

Lightweight HGU-55/P (CE) features an optional field modification

kit to fully integrate the helmet system with the complete manworn

COMBAT EDGE pressure breathing for G system (PBG) that is used

to reduce the probability of G-induced loss of consciousness

(GLOC) during high performance flight. The Lightweight HGU-55/P

(CE) helmet assembly is a high performance head protective system,

with enhanced CG and maximum stability. HGU-55/P helmets are

designed with greater cut back across the top frontal opening

and at the 3 and 9 clock positions to provide improved peripheral

vision for aircraft personnel in high performance fighter/attack

aircraft. The

Lightweight HGU-55/P (CE) features an optional field modification

kit to fully integrate the helmet system with the complete manworn

COMBAT EDGE pressure breathing for G system (PBG) that is used

to reduce the probability of G-induced loss of consciousness

(GLOC) during high performance flight. The Lightweight HGU-55/P

(CE) helmet assembly is a high performance head protective system,

with enhanced CG and maximum stability. HGU-55/P helmets are

designed with greater cut back across the top frontal opening

and at the 3 and 9 clock positions to provide improved peripheral

vision for aircraft personnel in high performance fighter/attack

aircraft.

The Lightweight HGU-55/P (CE) helmet utilizes

a urethane-coated nylon bladder installed between the Thermoplastic

Liner (TPL®) and the energy absorbing liner in the rear of

the helmet. A PBG feed tube connects the bladder to a quick-disconnect

mounted on the exterior shell of the helmet. The quick-disconnect

interfaces with the PBG supply hose and connector from the COMBAT

EDGE MBU-20/P Oxygen Mask. During the PBG phase, the bladder

inflates to provide automatic mask tensioning at high G, to hold

the mask in position under pressure.Specially contoured polycarbonate

visors, in clear and neutral gray, are provided to interface

with the low-profile COMBAT EDGE MBU-20/P Oxygen Mask. |

|

Leather nametag

|

|

SRU-21/P Survival Vest

|

|

|

|

|

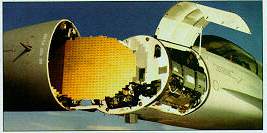

AN/APG-66/68

Radar

The AN/APG-66

is a pulse-doppler radar designed specifically for the F-16 Fighting

Falcon fighter aircraft. It was developed from Westinghouse's

WX-200 radar and is designed for operation with the Sparrow and

AMRAAM medium-range and the Sidewinder short- range missiles.

APG-66 uses a slotted planar-array antenna located in the aircraft's

nose and has four operating frequencies within the I/J band.

The modular system is configured to six Line-Replaceable Units

(LRUs), each with its own power supply. The LRUs consist of the

antenna, transmitter, low-power Radio Frequency (RF) unit, digital

signal processor, computer, and control panel. The AN/APG-66

is a pulse-doppler radar designed specifically for the F-16 Fighting

Falcon fighter aircraft. It was developed from Westinghouse's

WX-200 radar and is designed for operation with the Sparrow and

AMRAAM medium-range and the Sidewinder short- range missiles.

APG-66 uses a slotted planar-array antenna located in the aircraft's

nose and has four operating frequencies within the I/J band.

The modular system is configured to six Line-Replaceable Units

(LRUs), each with its own power supply. The LRUs consist of the

antenna, transmitter, low-power Radio Frequency (RF) unit, digital

signal processor, computer, and control panel.

The system has ten operating modes, which

are divided into air-to-air, air-to-surface display, and sub-modes.

The air-to- air modes are search and engagement. There are six

air-to-surface display modes (real beam ground map, expanded

real beam ground map, doppler beam- sharpening, beacon, and sea).

APG-66 also has two sub-modes, which are engagement and freeze.

In the search mode APG-66 performs uplook

and downlook scanning. The uplook mode uses a low Pulse Repetition

Frequency (PRF) for medium- and high-altitude target detection

in low clutter. Downlook uses medium PRF for target detection

in heavy clutter environments. The search mode also performs

search altitude display, which displays the relative altitude

of targets specified by the pilot.

Once a target is located via the search mode,

the engagement sub-mode can be used. Engagement allows the system

to use the AMRAAM , Sidewinder , and Sparrow missiles. When engaging

the Sidewinder , APG-66 sends slaving commands that slaves the

missile's seeker head to the radar's line-of-sight for increased

accuracy and missile lock-on speed. An Operational Capability

Upgrade (OCU) was developed to modify the APG-66 to use the AMRAAM

missile. The OCU is designed to provide the radar with the necessary

data link to perform mid-course updates of the missile. The Sparrow

's semi-active homing seeker is facilitated in the engagement

mode by a Continuous Wave Illuminator (CWI). The CWI also permits

APG-66 to be compatible with Skyflash and other missiles with

similar semi-active homing seekers.

Target acquisition can be manual or automatic

in the track mode. There are two main manual acquisition modes,

single-target track and situation awareness. The situation awareness

mode performs Track-While-Scan (TWS), allowing the pilot to continue

observing search targets while tracking a specific target. While

in this mode, the search area does not need to include the tracked

target's sector.

Four Air Combat Maneuvering (ACM) modes are

available for automatic target acquisition and tracking. In the

first ACM mode, a 20 x 20-deg Field Of View (FOV) is scanned.

This FOV is equal to that of the Head Up Display (HUD). Once

a target is detected, the radar performs automatic lock-on. The

second ACM mode's FOV is 10- x 40-deg, offering a tall window

that is perpendicular to the aircraft's longitudinal axis; this

proves especially useful in high-G maneuvering situations. A

boresight ACM mode is used for multiple aircraft engagement situations.

The boresight uses a pencil beam positioned at 0-deg azimuth

and minus 3-deg elevation to "spotlight" a target for

acquisition. This is especially useful in preventing engagement

of friendly aircraft. A slewable ACM mode allows the pilot to

rotate the 60- x 20-deg FOV. The automatic scan pattern gives

the pilot up to 4 sec of time. This mode is designed for use

when the aircraft is operating in the vertical plane or during

stern direction conversion.

The slant range measurement to a designated

surface location is generated by the Air-to-Ground Ranging (AGR)

mode. This real-time mode acts with the fire-control system to

guide missiles in air-to-ground combat. AGR is automatically

selected when the pilot selects the appropriate weapons deployment

mode.

Terrain in the aircraft's heading is displayed

via the real beam ground map mode. The radar provides the stabilized

image mainly as a navigational aid in ground target detection

and location. An extension of this mode is the expanded real

beam ground map. The expanded real beam ground map provides a

4:1 map expansion of the range around a point designated by the

pilot via the display screen's cursor.

Doppler Beam Sharpening (DBS) is available

to further enhance the higher resolution of the expanded real

beam ground map. This mode, which enhances the range and azimuth

resolution by 8:1, is only available from the expanded real beam

ground map mode.

In the Beacon mode the system performs navigational

fixing. It also delivers weapons relative to ground beacons and

can be used to locate friendly aircraft that are using air-to-air

beacons.

The high-clutter environment of the ocean

surface is countered in the sea mode. There are two sub modes

in the sea mode. The first sub-mode, Sea-1 is frequency-agile

and non- coherent to locate small targets in low sea states.

The second sub-mode, Sea-2, is fully coherent, with doppler discrimination

for the detection of moving surface crafts in high sea states.

The freeze sub-mode can only be accessed through

the air- to-ground display modes. It pauses the display and halts

all radar emissions as soon as the freeze command is received

via the controls. The aircraft's current position continues to

be shown on the frozen display. This mode is useful during penetration

operations against stationary surface targets when the aircraft

needs to prevent detection of its signals, yet continue to close

in on the target.

The system's displays include the control

panel, HUD, radar display, with all combat-critical controls

integrated into the throttle grip and side stick controller.

The modularity of the LRUs allow for shortened

Mean Time To Repair (MTTR) since they can simply be replaced,

involving no special tools or equipment. The MTTR has been demonstrated

to be 5 minutes, with 30 minutes for replacement of the antenna

unit. APG-66 has also demonstrated a Mean Time Between Failure

(MTBF) of 97 hours in service, but the manufacturers contend

that it has achieved 115 hours. A cockpit continuous self-test

system monitors for malfunctions. The manufacturers claim that

the system's Built-In-Test (BIT) routine can isolate up to 98%

of the faults to a particular LRU in the event of a malfunction.

A new version of the AN/APG-66, designated

the AN/APG-66(V)2 is being installed in F-16A/B aircraft as they

are modernized in the Midlife Update program. The equipment is

lighter and provides greater detection range and reliability

for the modernized F-16s.

|

ACES II

|

|

The ACES II (Advanced Concept Ejection

Seat) is considered a smart seat since it senses the conditions of the ejection and selects

the proper deployment of the drogue and main parachutes to minimize

the forces on the occupant. The seat is a derivative of the Douglas

Escapac seat. conditions of the ejection and selects

the proper deployment of the drogue and main parachutes to minimize

the forces on the occupant. The seat is a derivative of the Douglas

Escapac seat.

Removal from the aircraft is by a three part pyrotechnic sequence.

A gun catapult provides the initial removal of the seat from

the aircraft. A rocket sustainer provides zero/zero capability

to the seat. To prevent the seat from tumbling when the aircraft

is in a roll maneuver or there is a center of gravity imbalance,

another (smaller) rocket called a STAPAC is attached to a gyroscope.

This senses the motion and attempts to keep the seat from spinning

by automaticly providing a correcting force.

Once clear of the aircraft, the pitot - static system on the